MOBILE OBSCURA

—

Architectural timber frame structure

Design for Manufacture

Bartlett School of Architecture, London

2021

Following the design objectives of „observation“ and „time frame“ in combination with a special emphasis on timber as highly sustainable material, our team of seven generated the idea of an 3D projection space. The observer can enter the space, experience a space filling projection and interacted with it. The idea of the inhabitable camera was born.

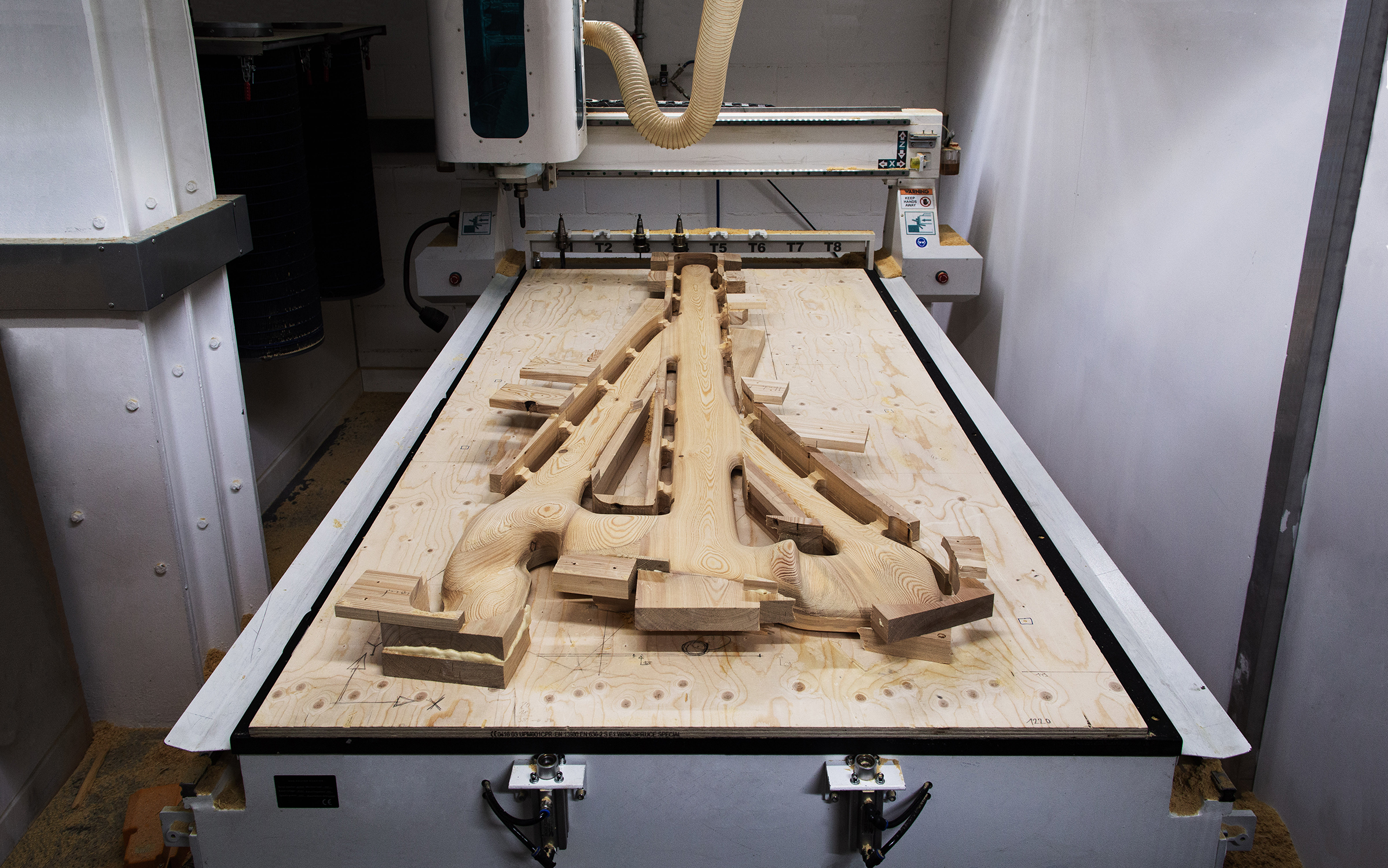

The design follows thereby the underlying principle of the camera obscura and works with two pinholes for a stereo projection. The main design question was, how the idea is translated in a timber frame construct, that is mainly manufactured with CNC technology. To achieve this, the design was broken down into single components with individually interlocking joints. Using a subtractive manufacturing method, we focused on the reduction of wastage through bespoke stock production for each component.

The design is durently in production, wherefore the following images serve as insight in the on-going process.

PAPIER MÂCHÉ MODELS

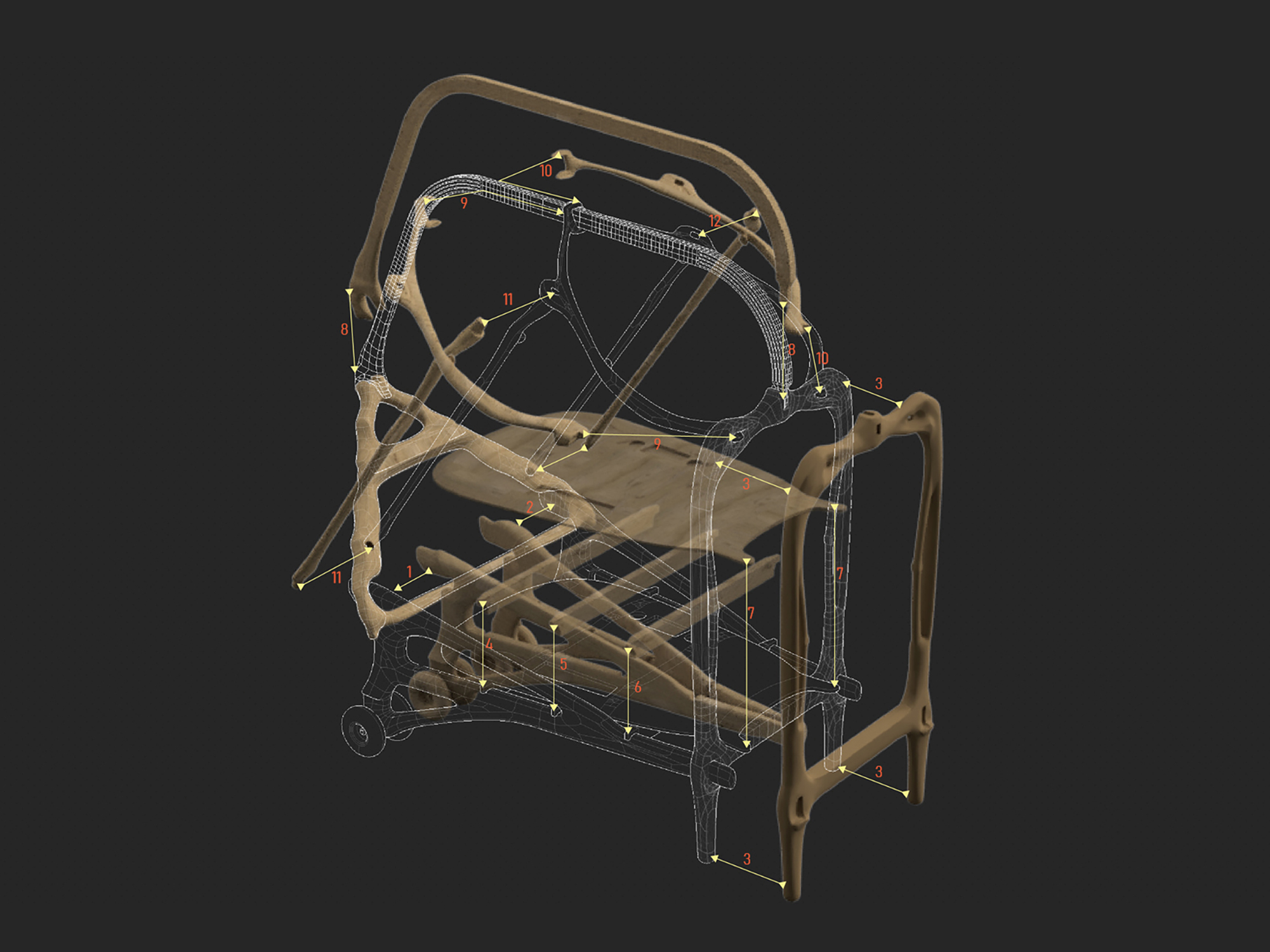

3D SCANS

of the models where essential to analyse and understand form and functionality of the models. The results where taken further back and helped to design and develop the final shape of the object.

of the models where essential to analyse and understand form and functionality of the models. The results where taken further back and helped to design and develop the final shape of the object.

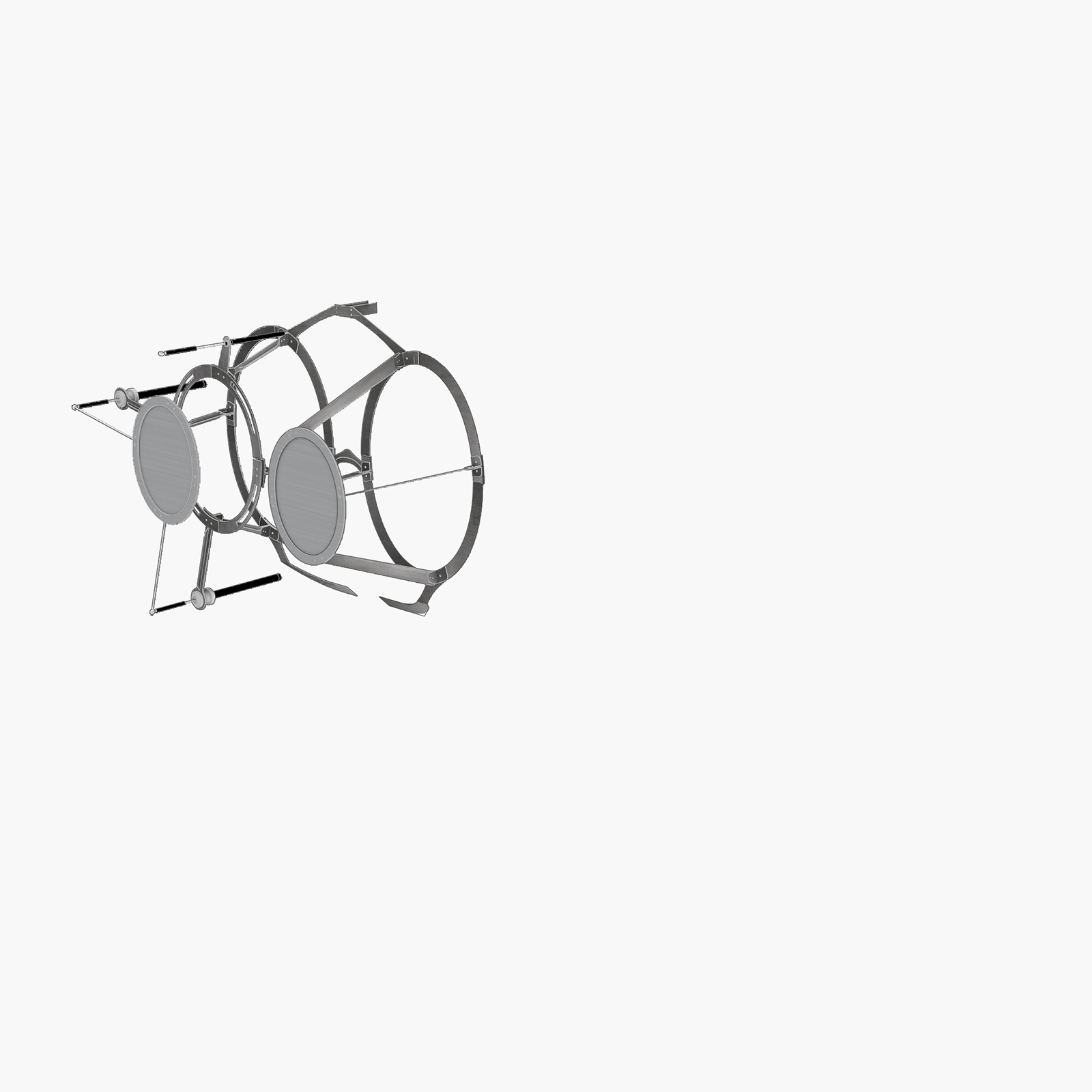

THE STRUCTURE

1

PINHOLES

![]()

2

TIMBER FRAME

![]()

3 MEMBRANE SPACE

Component on the machine bed after the milling process. The toolpath has almost eliminated the bespoke stock. A clear evidence for material efficiency. Only single pieces are left to mount the object.

Timber stock before and after machining.

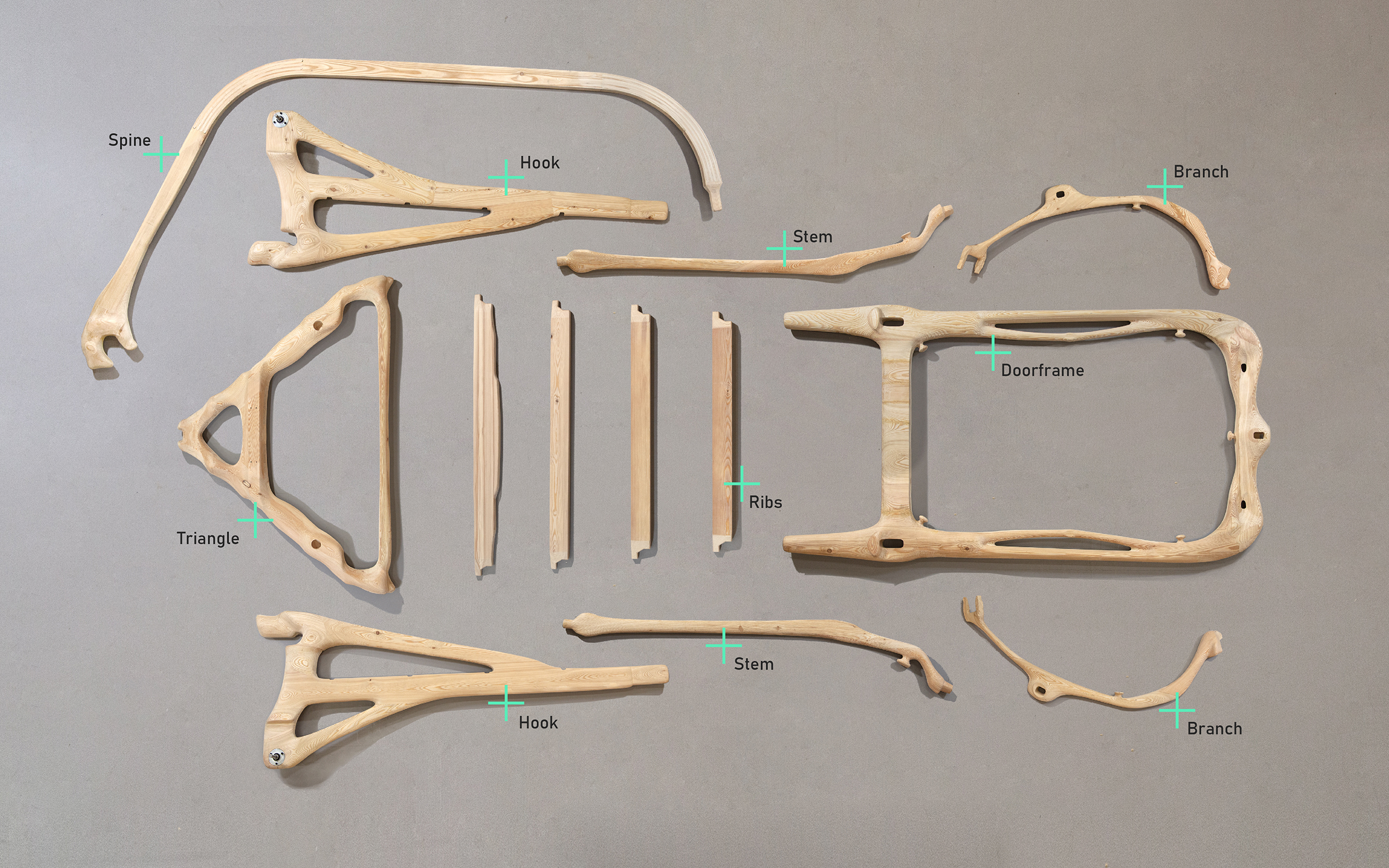

MANUFACTURED COMPONENTS

Making of the hybrid finger joint. Two beams with manufactured endings, interlocking through steambend connector pieces.

LAYOUT OF COMPENENTS

THE TIMBER FRAME

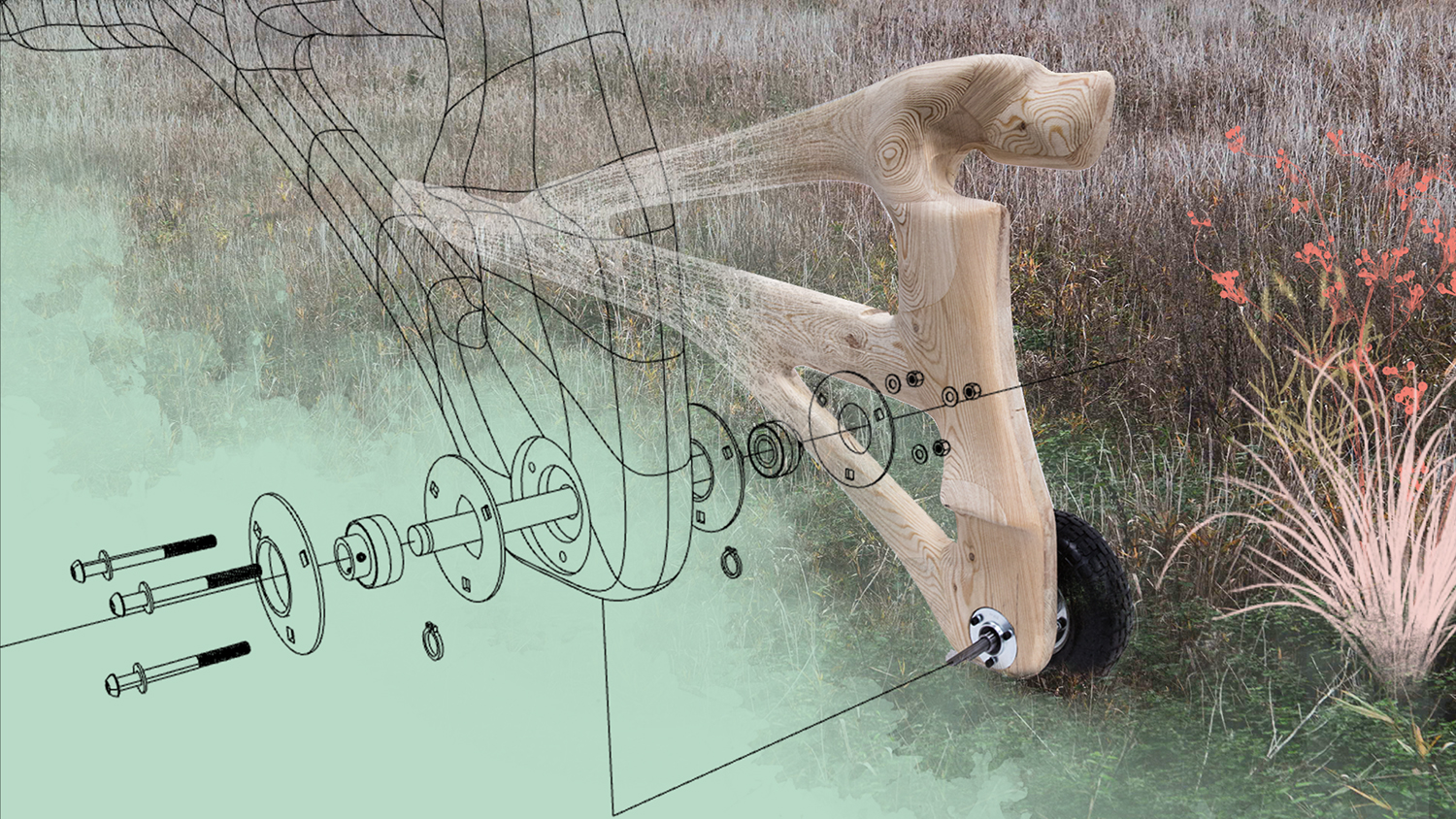

Image of the structure and strategy to assemble the single components.

THE HOOK COMPONENT

Added ball bearings guiding the axle. This example showcases how organic shapes can be combined with off-the-shelf products through early integration into the process of manufacturing.

DETAILS SHOWING THE MACHINED TOOLPATH

CLOSE-UP OF INTERLOCKING ELEMENTS